Academy

Dental 3d printing

3d printing is becoming more and more widespread in dentistry. In the near future this technology is expected to completely replace traditional dental modeling. 3d printing is faster, more precise and cost effective due to the automation potential.

Why thousands of dentists and orthodontists all over the world switch to the 3d printing?

-

Quality. Combined with intraoral scanners and CAD/CAM modelling, 3d printing helps to reduce human error to the minimum;

-

Speed. Average desktop 3d printers can print up to 16 models in 8 hours

-

Cost savings. escalating labor costs and shortage of dental technicians promotr migration to 3D-printed dental appliances;

-

Biocompatibility and precision. Thanks to the digitalisation of the production process and modern printing materials, dental appliances fit perfectly the unique anatomy of the patient;

Which dental products and appliances can be 3d printed?

-

Patterns of crowns & bridges - Development of a wide range of biocompatible materials combined with the precision of CAD/CAM technology allows to produce high quality, cost and time effective dentures that fit perfectly the patient’s anatomy

-

Models - Plaster or stone models are slowly becoming a thing of the past, as more and more dentists and dental technicians switch to digital. Models are used in various ways, mostly for the diagnostics, but also for producing clear aligners;

Surgical guides are used as a template for implant therapy. They are usually printed as a full arch guide surgical guide, designed for the single-site dental implants.

-

Occlusal splints. Bite-stabilization appliances can now be 3d printed with bio compatible materials. The result is more cost effective and precise than analog splints.

-

Night guards. Another dental appliance that can be 3d printed directly, without printing the dental model first. They are used to treat bruxism, teeth grinding or jaw clenching

-

Clear aligners. Orthodontic appliances for bite correction and teeth straightening, an innovative and convenient alternative to the metal braces. Nowadays clear aligners are produced using the 3d printed models with following vacuum forming. Existing printing materials do not allow the direct printing of the aligners yet. The thickness of the material used for aligners production is usually 0.75mm, this is too thin for direct printing. We expect the appearance of the materials required for the direct 3d aligner printing over the next 2-3 years.

What is the workflow for the 3d printing of all above mentioned products and appliances?

-

Collect the patient data. Digital models can be created using modern intraoral scanners or scanning the plaster models with a desktop scanner.

-

Design and plan. The most complicated part of production, requiring both modelling and clinical experience

-

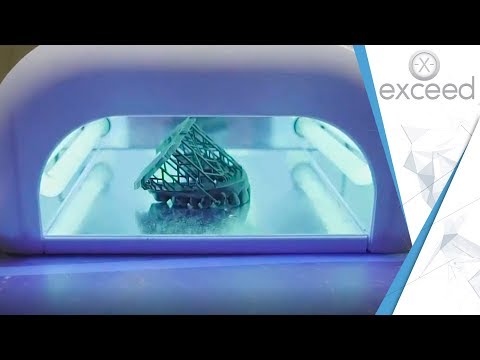

3d printing and production. Use generated STL printing files and post process models and appliances according to the technological process requirements

-

Delivering and installation. Chairside part of the treatment process handled by the dentist

eXceed handles the Design and Plan part for the aligners production. With more than 35000 delivered aligners plans delivered up to date, eXceed is one of the world’s leaders in orthodontic treatment planning. New “In-Office aligners production” approach allows saving up 70% on aligners lab fees, compared with traditional full-service providers.

What 3d printers are compatible with eXceed?

eXceed is an open system that works with a wide range of equipment. The most popular models among our clients are from Formlabs, Sprintray, Nextdent and Structo.

Do you recommend FDM, DLP or SLA printers?

We work with all types, although the printing outcome may vary from one model to another. Due to the broad variety of available models, we are not able to test them all.

You can always download some Sample STL printing files and send us the pictures of the printed models per email or Whatsapp. Our Technical department will prove the quality of the models.

Please note that FDM printers usually place the models horizontally and directly on the platform without any supports. Sometimes it is hard to see the case ID and the step number of the model, which is very important when it comes to production.

Which printing methods are used by eXceed?

Our models are normally generated for vertical printing. It allows our clients to reduce printing time and save resin. However, not all cases are suitable for such a method.

How does it work?

-

Scan the patient

-

Submit the treatment data. Digital models, intraoral picture, OPTG and Treatment objectives

-

Approve the virtual 3d treatment plan

-

Get STL files for your 3d printer

-

-

Produce aligners in your office